The fashion industry is highly competitive, making it challenging for startups to break into the market. High production costs, strict MOQ, and the demand for quality materials can be overwhelming, even for well-funded startups. Finding a reliable manufacturer who understands your brand vision and delivers on time is no easy feat.

However, custom clothing manufacturers offer a solution. By providing tailored production services, startups can create unique designs that resonate with their target audience. This helps build a strong brand identity and allows startups to scale operations efficiently.

This guide will provide you with a comprehensive overview of custom clothing production. From understanding the basics to building sustainable partnerships, we’ll cover everything you need to make informed decisions for your brand.

Why Custom Clothing Production Matters for Startups

Custom clothing production frees startups from generic, off-the-shelf designs. Instead, you control every detail: fabric, stitching, prints, and labels.

Flexible MOQs

Custom manufacturers often offer flexible minimum order quantities. As long as you meet their MOQ, you can produce small batches of branded clothing according to market demand.

Brand Uniqueness and Storytelling

Custom production enables startups to create designs with a story. Whether through unique patterns, innovative materials, or eco-friendly production methods, custom clothing helps your brand stand out and build deeper connections with customers.

Scalability

Startups can begin with small production runs to test the market and scale up as demand grows. This flexibility ensures you don’t overproduce or overspend during the early stages.

Quality Control and Material Customization

Custom manufacturers allow startups to choose high-quality materials and customize every aspect of the production process. This level of control ensures your final product meets your brand standards and exceeds customer expectations.

How to Identify a Cost-Effective Clothing Manufacturer

After understanding the advantages and challenges of custom clothing production, the next step is to find a manufacturer that aligns with your brand goals and budget.

You can evaluate potential partners in the following ways:

Criteria for Evaluating Clothing Manufacturers

Low Minimum Order Quantity (MOQ)

Startups often begin with small-scale production to test the market. Look for manufacturers offering low MOQs to enable small-batch production without overspending.

Transparent Pricing Model

Avoid manufacturers with hidden fees or unclear pricing structures. Ensure you calculate the following costs:

Sample Fees: Verify manufacturers disclose all costs for pre-production samples.

Volume Discounts: Reliable manufacturers typically offer discounts for large orders, with bigger discounts for larger quantities.

Additional Costs: Be aware of potential expenses like import tariffs, shipping, or extra service fees.

Niche Market Expertise

If your brand focuses on a specific category, such as sustainable fabrics, activewear, or streetwear, partnering with manufacturers experienced in your niche can be highly beneficial. Specialized manufacturers often have the right materials, design knowledge, and production techniques to meet your brand’s needs.

Geographical Considerations

Location is also an important cost factor when choosing a manufacturer. You need to first understand the difference between a local clothing manufacturer and an overseas manufacturer:

Local Clothing Manufacturers

Advantages:

- Smooth communication, Shorter shipping distances,

- easier communication and quality control through site visits

- fewer import/export regulations and tariffs.

Disadvantages:

- Higher labor costs, larger upfront investments

- fewer fabric/material options compared to overseas manufacturers

Overseas Clothing Manufacturers

Advantages:

- Lower production costs, more cost-effective for large orders

- wider variety of materials and production techniques.

Disadvantages:

- Longer delivery times due to international shipping and customs clearance

- potential communication barriers requiring clear documentation and technical packages.

Whether to choose a local or overseas manufacturer depends on your budget, production volume, and quality expectations. Many startups choose to manufacture from overseas to better control costs and perfectly realize their designs.

How to Find Clothing Manufacturers?

Finding the right apparel manufacturer takes a lot of time upfront to research. A catalog of manufacturers can often be compiled using the following platforms and tools:

Online Platforms

Alibaba: A vast marketplace with global manufacturers offering production from small to large scale.

Maker’s Row: A platform focused on U.S. manufacturers, ideal for brands prioritizing local production.

ThomasNet: A directory of suppliers across North America, including those in the fashion industry.

Search Engines

Google: Search for custom clothing manufacturers using keywords like “custom clothing manufacturer,” “t-shirt manufacturer,” or “hoodie manufacturer.” You can also search by region, e.g., “clothing manufacturer in China” or “clothing manufacturer in Los Angeles.”

Facebook: Many garment factories are listed on Facebook, where you can filter by keywords.

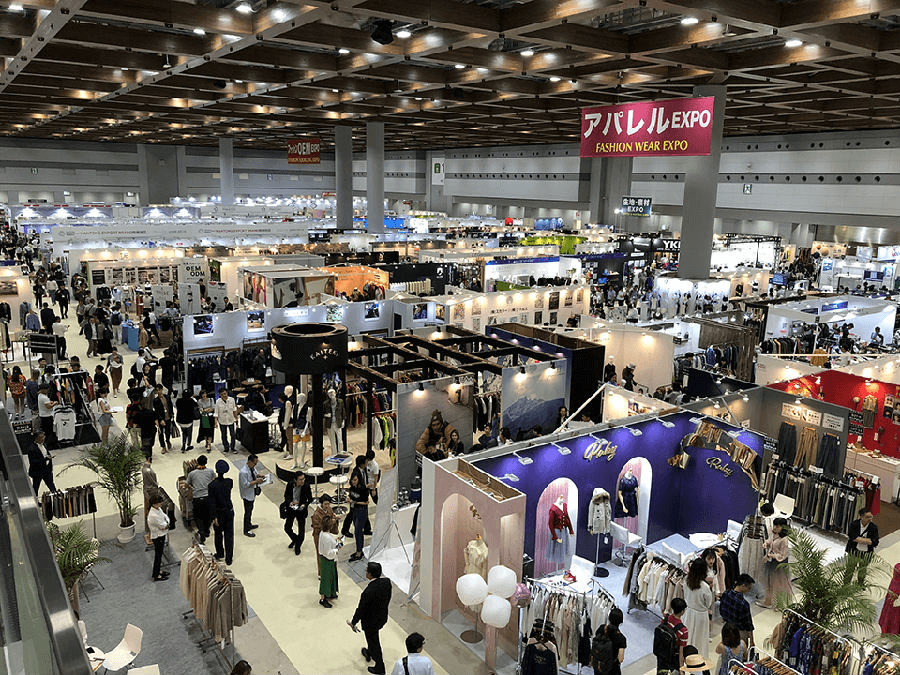

Trade Shows and Industry Events

Attending trade shows allows startups to meet manufacturers face-to-face, assess product quality, and build relationships. Notable fashion industry trade shows include:

- Magic Las Vegas (USA): A major sourcing event for apparel brands.

- Texworld Paris (France): A leading international textile and sourcing trade show.

- Canton Fair (China): One of the largest trade fairs, featuring numerous clothing manufacturers.

Startups-Focused Platforms

- Sewport: Connects startups with manufacturers based on specific needs and production goals.

- Fashion Index: A network designed to help emerging fashion brands find verified suppliers and service providers.

- Printful and Printify: Ideal for brands wanting to start with on-demand printing before scaling to full production.

By leveraging these resources, startups can identify cost-effective production partners that meet their budget and production needs.

Selecting the Right Partner

Once potential manufacturers are identified, it’s time to make a decision. Use the following criteria to review and choose manufacturers that align with your brand:

- Experience and Expertise: Look for manufacturers with experience, especially in your specific design style (e.g., streetwear, formal wear, or casual wear).

- Sample Production Capability: Many manufacturers offer sample production services. Use samples to assess if they can accurately execute your design vision. Ensure materials and craftsmanship meet your requirements.

- Production Capacity and Lead Time: Confirm manufacturers’ production cycles and delivery times align with your needs, particularly for large-scale orders.

- Communication and Responsiveness: Ensure manufacturers respond promptly, explain technical details clearly, and make adjustments based on feedback.

- Customization and Flexibility: Verify they can meet your design-specific needs, including material, printing, embroidery, and labeling customizations.

- Pricing and MOQ: Understand if their MOQ and pricing fit your budget. Flexibility in order quantities is crucial for startups.

- Equipment and Technology: Ensure they have modern equipment, especially for complex printing, embroidery, or specialty fabric handling.

- Certifications: Look for ISO, Fair Trade, or SEDEX certifications, which indicate commitments to quality, ethical practices, and environmental standards.

- References and Case Studies: Review other companies’ testimonials and request case studies to gauge their reliability and expertise.

- Payment Terms: Negotiate flexible payment terms, such as installment payments, to reduce upfront costs.

Building a Sustainable Partnership

After selecting a manufacturer, the next step is to establish a sustainable partnership to ensure smooth collaboration and long-term success.

Clear Communication and Shared Goals

Align on brand vision, design concepts, quality standards, and delivery timelines before starting production. Maintain regular communication, especially during production, to address issues and adjust goals as needed.

Trust and Transparency

Integrity is the foundation of long-term partnerships. Be transparent about production processes, quality management, pricing, and delivery schedules. Open communication fosters trust. Share your market demands and innovation plans to keep manufacturers informed about your direction.

Stable Order Volume

Consistent order volume is key to long-term partnerships. Avoid frequent order changes and plan production cycles in advance. Stable orders not only secure better pricing but also demonstrate your value as a long-term partner.

Quality Assurance

Set clear quality standards from the start and conduct regular product inspections. Address quality issues promptly with your manufacturer and implement solutions. Establish robust quality control processes to ensure each batch meets standards.

Adaptability to Market Changes

Market demands and trends evolve, requiring manufacturers to be flexible. Collaborate on adaptable production plans to quickly respond to changes, enhancing competitiveness and strengthening partnerships.

Problem-Solving Together

Challenges like production delays or material issues may arise. Maintain a collaborative attitude, communicate promptly, and brainstorm solutions to minimize losses for both parties.

Review and Feedback

Conduct review meetings with manufacturers from time to time to assess the past period of cooperation and discuss room for improvement. Feedback is actively provided to point out shortcomings and to jointly discuss ways to increase productivity, reduce errors, and improve quality.

By implementing these strategies, you can build a long-term, stable partnership with your manufacturer. This not only facilitates product launches but also provides strong support for your brand’s ongoing growth.

Conclusion

For startups, the success of custom clothing production hinges on flexibility, transparency, and strategic partnerships. Start small with limited production runs to validate designs and refine them based on feedback. Remember, the right manufacturer isn’t just a supplier—they’re a collaborator in your brand’s journey.

Ready to get started? Feel free to share your questions or experiences below.